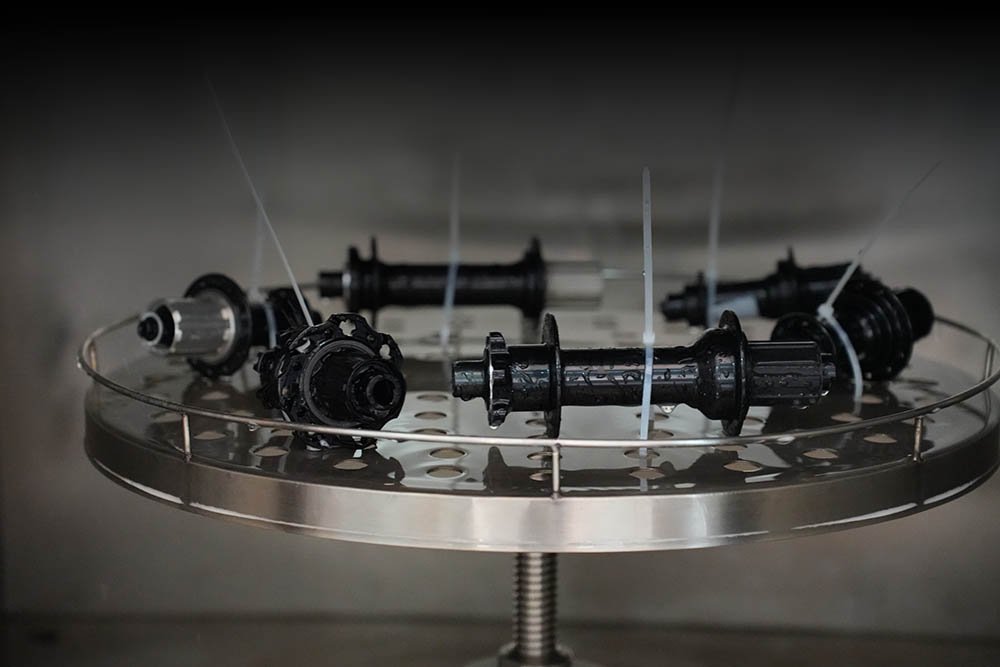

Precision-Engineered Hubs for the World’s Finest Bicycles.

Premium Materials: We exclusively use 6061-T6 Aluminum for hub shells (perfect strength-to-weight ratio) and 7075 Aluminum for axles (maximum stiffness and durability).

High Capacity: With a monthly output of 10,000 sets, we support both boutique brands and large-scale distributors.

Advanced CNC Mastery: Beyond hubs, our fleet of CNC machines allows for the customization of complex bike components with micron-level tolerances.

Certified Safety: Every batch undergoes rigorous fatigue, load, and salt-spray testing to ensure 100% reliability in extreme racing conditions.

High-performance Road, MTB, BMX, and Track hubs. 10,000 sets monthly capacity. Your vision, our CNC precision.

Road bike hubs

Lightweight & high-performance hubs designed for road cycling, optimized for speed and efficiency.

MTB bike hubs

Durable hubs built to withstand rough terrain, with enhanced strength and reliability.

BMX bike hubs

Heavy-duty hubs for BMX riding, engineered for impact resistance and quick acceleration.

Track bike hubs

Fixed-gear hubs for track cycling, precision-machined for consistent performance on the velodrome.

Customization Capabilities

100% Customized in Appearance, Color, and Functionality

Custom Specifications

We tailor hubs to your exact requirements: axle length, flange diameter, spoke count, color, and branding.

CNC Machining

Advanced CNC machines enable precise manufacturing of complex hub designs with tight tolerances.

Custom Finishes

Anodized, painted, or polished finishes in any color to match your brand identity and design needs.

When the hubs on wheelset

Precise, Strong, Light

Korstead is winning over customers with its quality.

Premium bike hubs are required to pass stringent testing processes

Showcase your ability to act as an extension of the client’s R&D team.

Step 1: Engineering: Send us your 2D/3D CAD files or let our engineers design from scratch.

Step 2: Branding: Laser-etching, CNC engraving, or custom water-transfer decals.

Step 3: Finishing: High-quality anodizing in over 12 colors (Oil slick, Matte Black, Chrome, etc.).

Step 4: Spec Selection: Choose your bearing grade (Steel vs. Ceramic) and engagement angle.

Bicycle hub waterproof test

Production equipment

Fatigue test

News

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!